We hear from our Strategic Advisor Sterling Crew about how the food industry is on the cusp of a revolution, one which will combine new technologies and techniques to change the very way our food is produced.

The new industrial revolution

We are in the midst of a new industrial revolution, enabled by new technologies used in the management of manufacturing and the control of the supply chain. It’s a world where food factories will now have machines augmented with wireless connectivity and smart sensors connected to systems able to visualise the entire production line, to control and make autonomous decisions. This is no longer in the realm of science fiction, it is happening now, fundamentally changing the way we work, shaping the future of the food industry and making our factories and operations smarter.

There is a significant trend towards automation and data exchange in food manufacturing technologies and processes. These new technologies will provide useful insight into the production of food. The data collected can to be processed with advanced analytical and algorithmic tools, in order to generate meaningful information. Currently such technology is found only in the largest of food enterprises, but this will change as the systems become more affordable and available to food businesses of every size. We could even see their adoption within single kitchens.

The new technologies

The new technologies involved in this food revolution include the Internet of Things (IoT), Artificial Intelligence (AI), smart sensor technology and blockchain. Adoption of these new technologies will make smart food operations a reality.

The Internet of things

The IoT and the cloud are essential components of this new revolution. IoT enables new forms of interconnection by using the cloud environment where data is stored, allowing greater access to technology and information, facilitating the ability for people, devices, smart sensors, and machines to connect and communicate with each other. This greater level of transparency allows food business operators to collect vast amounts of data and information from all aspects of the manufacturing operation, even from across a network of remote satellite catering sites. This enhanced visibility will help food teams make better informed and smarter food safety, quality and performance choices that will drive continuous improvement.

Artificial Intelligence

The development of AI means computers can now perform tasks normally requiring human intelligence, such as visual perception, speech recognition and decision making at super speeds beyond the capability of humans. The food organisation’s computers could be connected and able to communicate with one another without human involvement. The technology has the ability to support humans by accumulating and interpreting information, to assist in the making of informed decisions and resolving of critical problems at brief notice. AI could also make decisions autonomously, only escalating key decisions to human operators on a need to know basis. AI is also being used to identify unsafe foods. Researchers have trained machine learning algorithms to read online Amazon reviews for indications that a food product would be recalled by the FDA. It does this by learning to differentiate between reviews that are related to past recalls and those that are not. AI speeds up the detection process, leading to early identification and ultimately, more comprehensive, faster and safer recalls.

5G

Currently being rolled out across the UK 5G is the fifth generation of mobile internet connectivity, delivering faster data download and upload speeds, wider coverage and more stable connections. It will enable the adoption of other new digital technologies and is the foundation to making many of these technologies a reality. As 5G will deliver nationwide fast speed gigabit connections, it will support greater, more automated data collection across the complete food supply chain. By delivering greater bandwidth and allowing low latency data transfers for real-time information distribution. Once fully operational it will provide a greater networking capability with the capacity to handle multiple inputs such as those from smart sensor devices.

Smart sensor devices

We are seeing the adoption of smart sensor devices – devices that take input from the physical environment and use built-in computers to perform predefined functions upon detection of an input, processing the data before passing it on. For example, in the monitoring and the control of refrigeration temperatures. Smart sensors are also becoming personal, such as the use of augmented reality glasses, which provide an interactive experience of the real-world environment where objects are enhanced by computer generated perceptual information. Not only can such glasses see and analyse what the food handler is doing, but they also feedback information regarding any detected unsafe food practices. They can even instantly train the handler with the use of videos and on-screen information.

Blockchain

Blockchain is a shared, immutable ledger for recording the history of transactions. It is called blockchain because all the transactions are sorted into continuously growing lists of records called blocks and each block is chained to the ones before it, all the way back to the very first transaction, using sophisticated mathematical algorithms. The use of blockchain in the food supply chain was until fairly recently the subject of speculation. Now blockchain is a reality, with the world’s largest retailer Walmart making it a condition of trading in its green salad category. Blockchain is a collaborative solution that has the potential to revolutionise traceability and transparency of food across the supply network from farm to fork, making traceability possible in just seconds and minutes as opposed to weeks and months.

Consumer choice

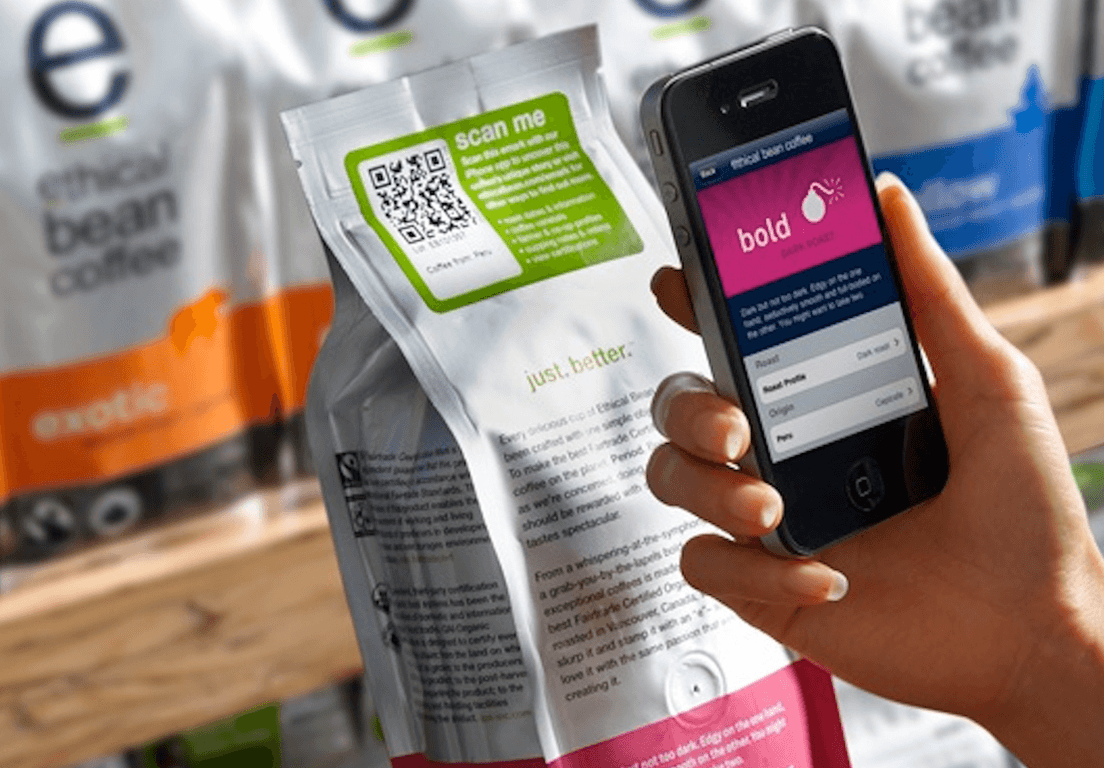

As well as improving food safety, quality and reducing the potential for food fraud, new technology such as blockchain has the capability to empower and enhance the consumer experience. Many consumers are unaware of where their food comes from and how it is produced. Blockchain linked to the IoT will make it easier for consumers to track the content and origins of foods, enabling them to make a more informed choice about the food they eat by directly connecting them with producers, via integration with other technologies, such as smartphones. With their phone and a QR code, consumers could scan their food and view a complete history of its journey from farm to fork, enabling them to personally validate the provenance of their purchases by tracking foods along the supply chain.

A glimpse into the future

In the very near future it will become commonplace to see connected machines and smart sensors in food operations both big and small collecting vast volumes of data. AI will enable the analysis of data and its conversion into valuable insights to inform management decisions. The future is happening around us and we must rise to the challenge to meet it, thriving in the opportunities presented by this new industrial revolution.

Through award-winning software Dynamic Risk Indicator is revolutionising the way companies conduct their compliance. An innovative web-based software solution designed to improve visibility and enhance compliance, Dynamic Risk Indicator is the only risk mitigation platform able to calculate an organisations’ overall risk score. Contact us today to discover how DRI can cut the complexity from compliance in your businesses.